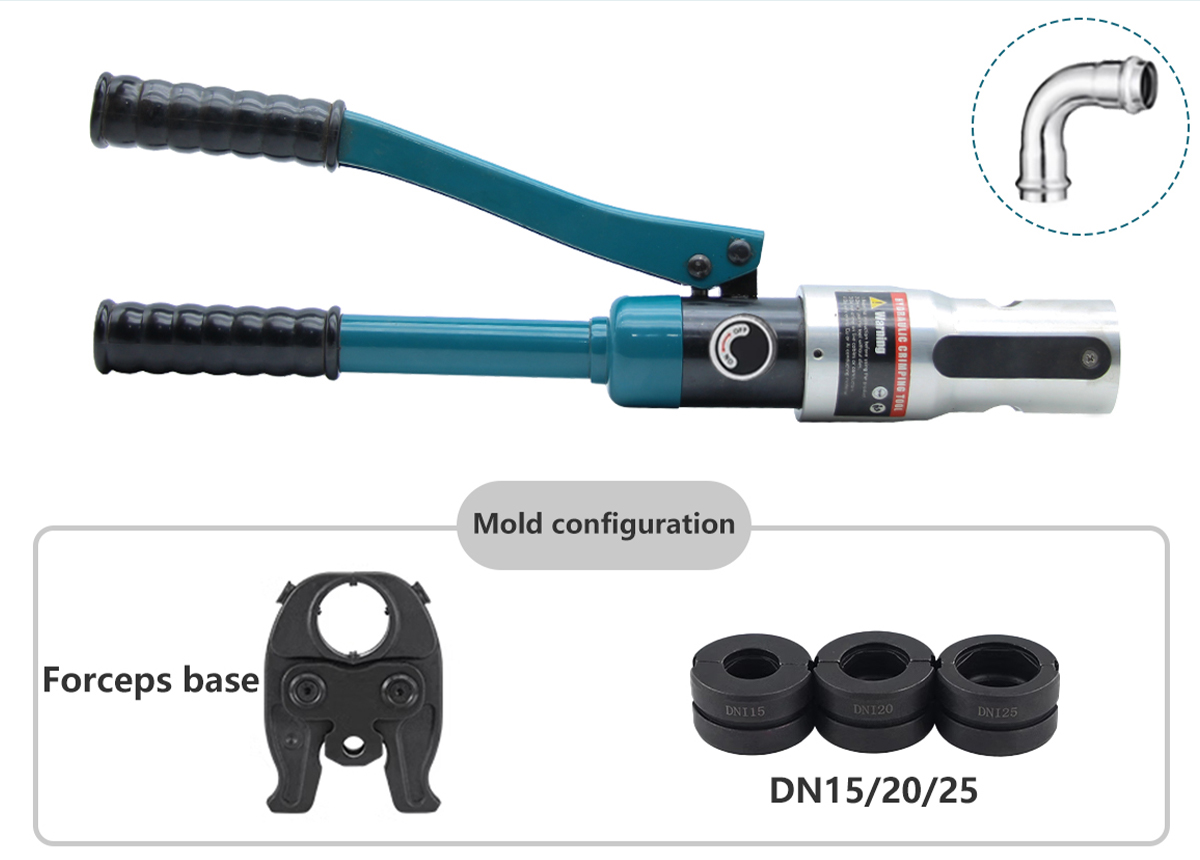

Plumbing industry.

| Output | 60KN |

| N.w./G.w. | 2.5kg/5.5kg |

| Stroke | 30MM |

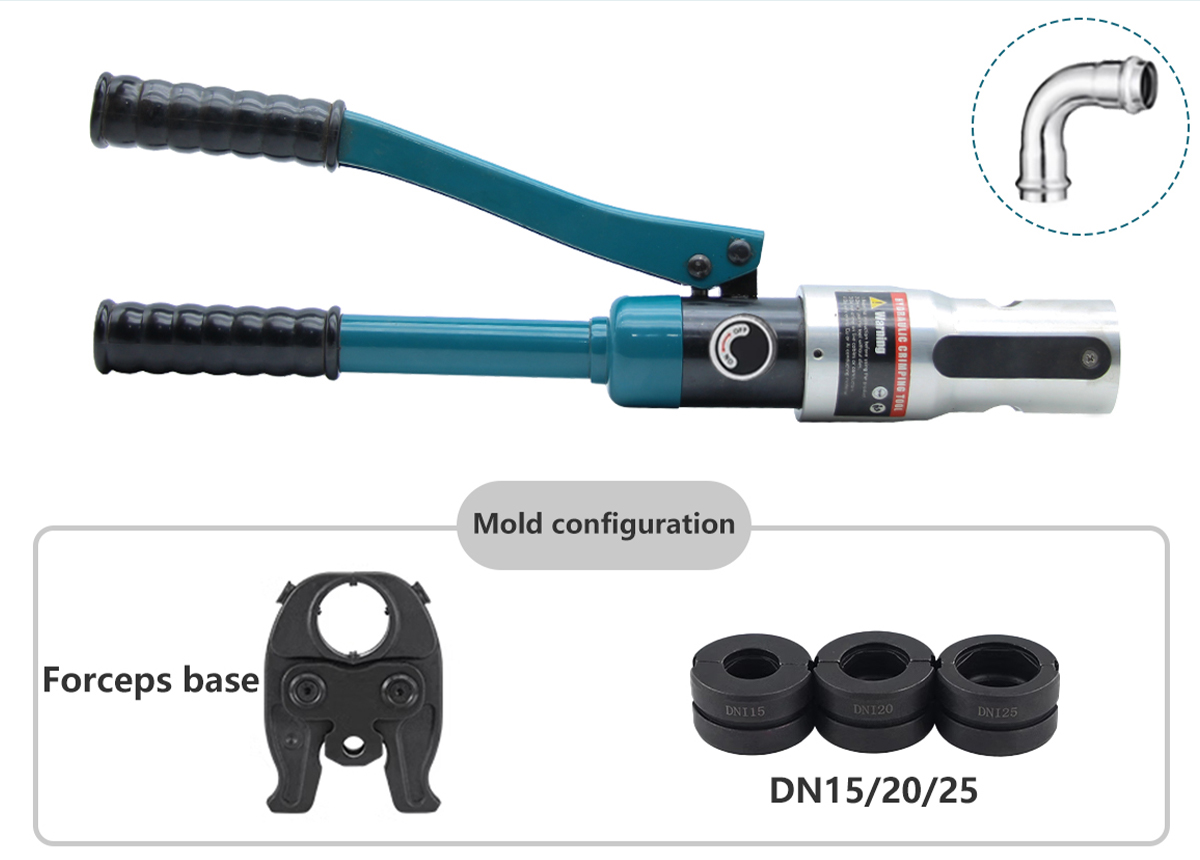

| Dies range | DN15/DN20/DN25 |

| Output | 60KN |

| N.w./G.w. | 2.5kg/5.5kg |

| Stroke | 30MM |

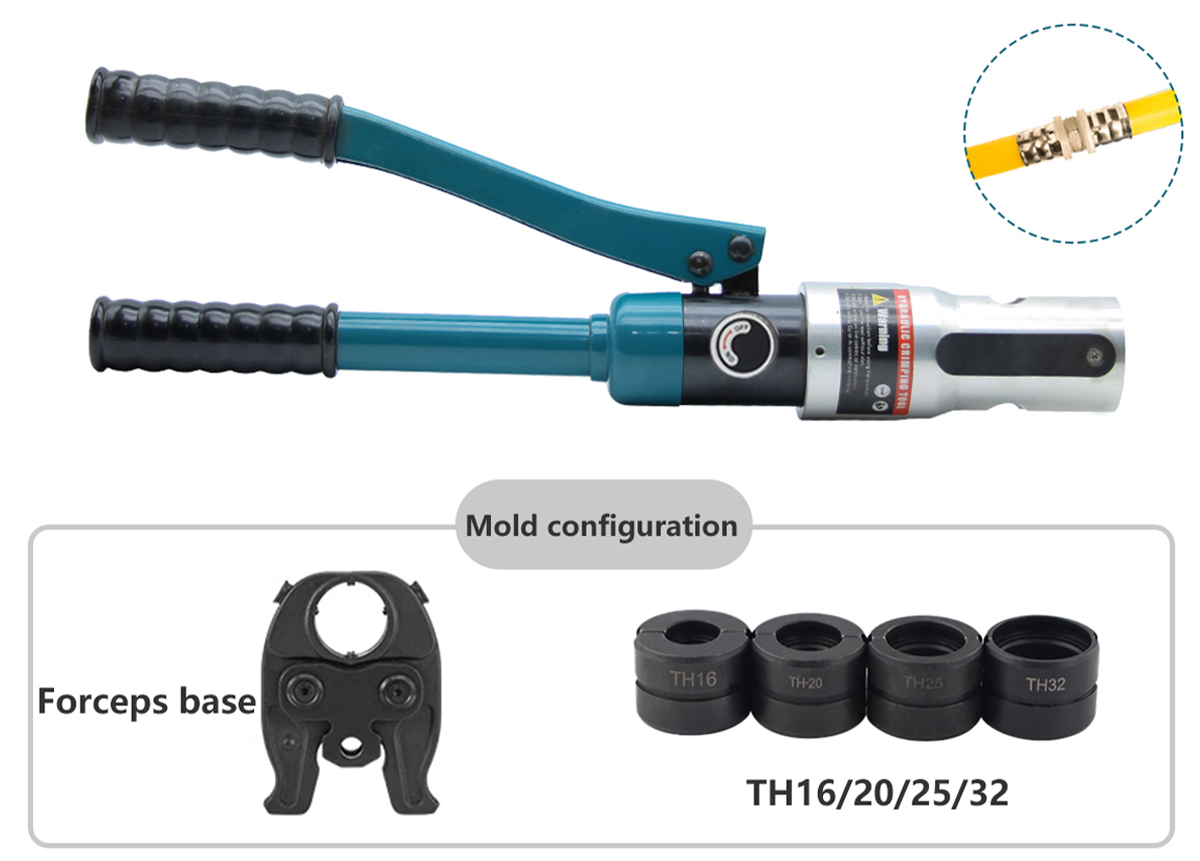

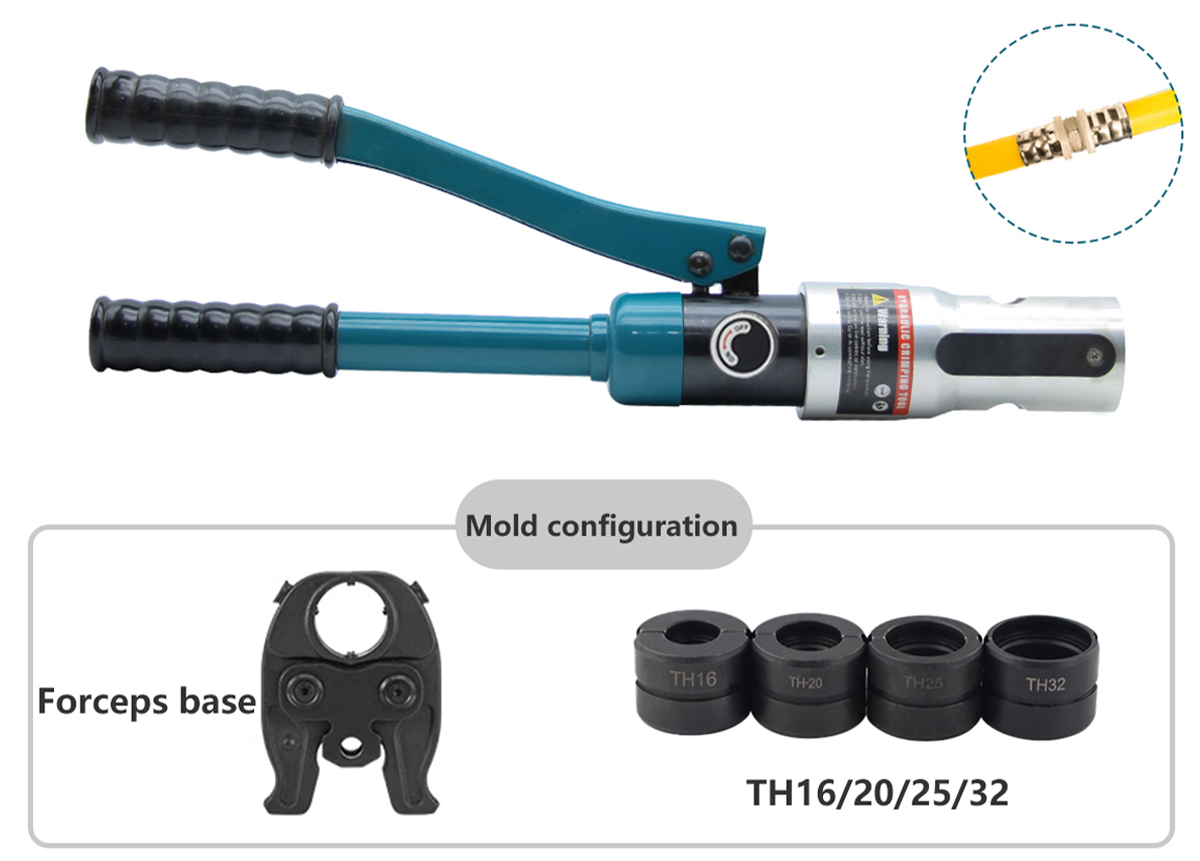

| Dies range | TH16/TH20/TH25/TH32 |

| Output | 60KN |

| N.w./G.w. | 2.5kg/5.5kg |

| Stroke | 30MM |

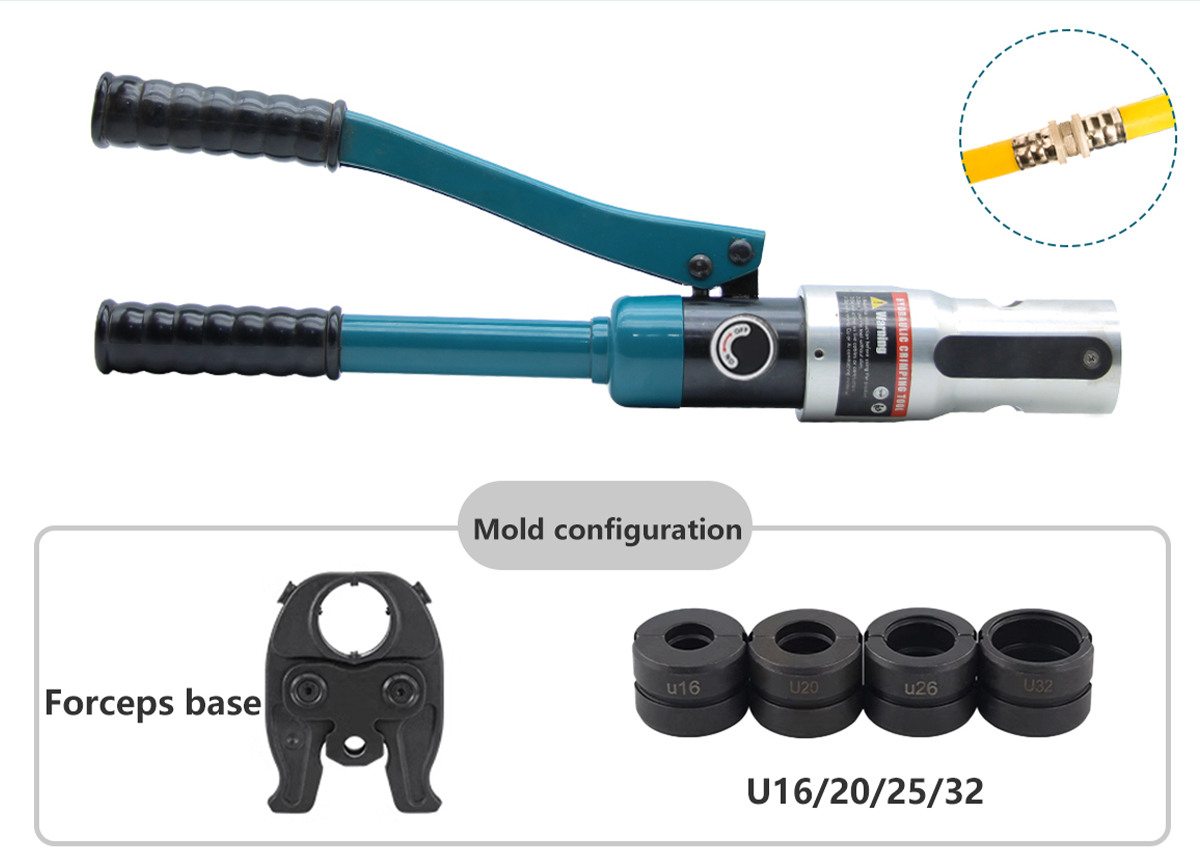

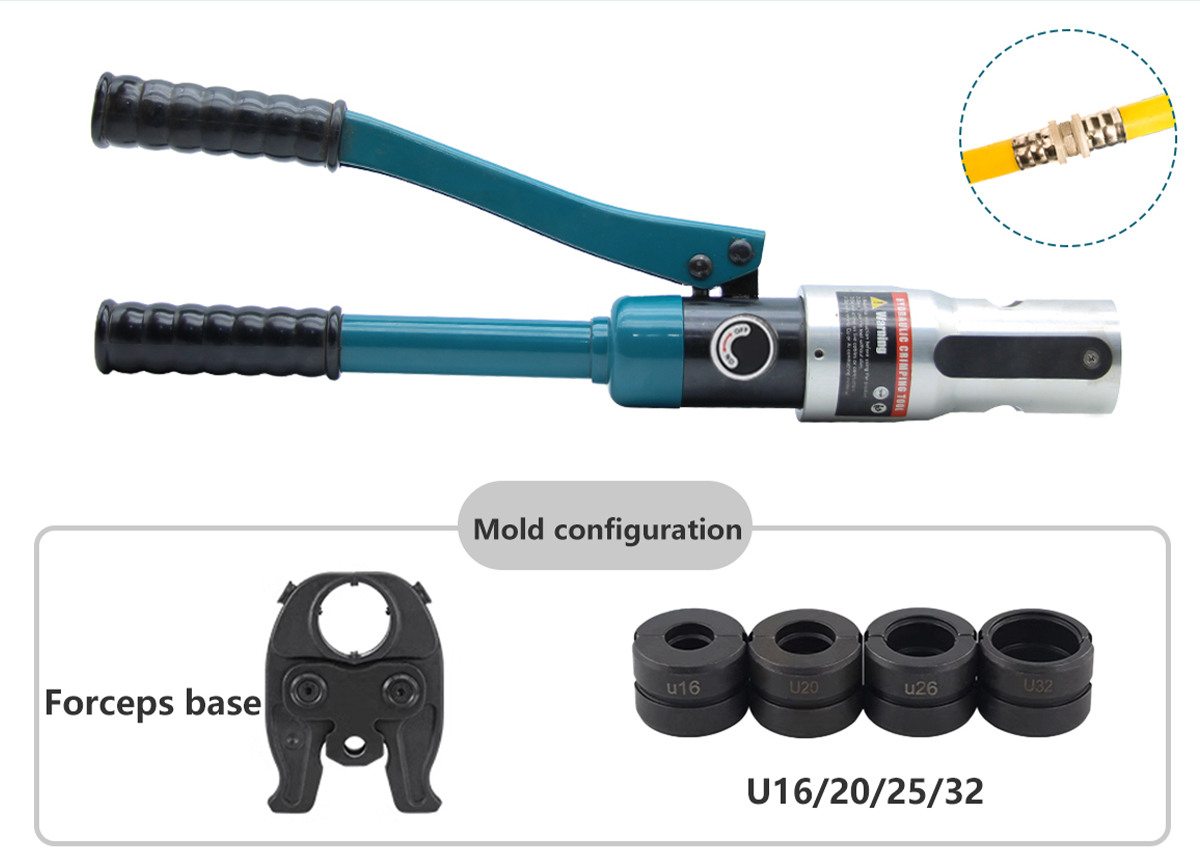

| Dies range | U16/U20/U25/U32 |

When precision, reliability, and convenience are paramount in crimping operations, Battery Powered Hydraulic Crimping Tools emerge as the ultimate solution. Designed to meet the diverse needs of electrical, construction, and industrial professionals, these cutting-edge tools combine advanced hydraulic technology with battery-powered convenience, ensuring effortless performance and portability in every application.

Unmatched Crimping Performance

Battery Powered Hydraulic Crimping Tools are engineered for delivering superior crimping performance. These tools generate consistent and powerful hydraulic pressure, making them ideal for crimping a wide range of materials, including copper and aluminum connectors, lugs, and terminals. With crimping capacities that often exceed traditional manual tools, they guarantee secure and precise connections, enhancing operational safety and longevity in electrical installations.

The tool’s intelligent design ensures uniform crimping pressure across the connector surface, reducing the risk of failure and improving the integrity of the joint. This makes it a perfect choice for professionals handling critical applications such as power grids, telecommunications, and large-scale construction projects.

Lightweight and Portable Design

Portability is a key feature of Battery Powered Hydraulic Crimping Tools. These tools are crafted with lightweight materials and ergonomic designs, allowing users to carry and operate them effortlessly, even in tight or elevated spaces. The battery power eliminates the need for cumbersome external power sources, offering unparalleled freedom of movement. This portability is especially valuable for field technicians who frequently move between sites and require reliable, adaptable tools for various tasks.

Efficient and Time-Saving Operations

Speed and efficiency are at the core of Battery Powered Hydraulic Crimping Tools. The advanced battery technology ensures quick charge times and long-lasting performance, allowing users to complete multiple crimping tasks on a single charge. This eliminates downtime and boosts productivity, making the tool an invaluable asset in fast-paced environments.

Additionally, the hydraulic mechanism requires minimal physical effort, significantly reducing operator fatigue during extended use. This feature is particularly beneficial in demanding industrial settings, where repetitive crimping can otherwise become labor-intensive.

User-Friendly Features

Battery Powered Hydraulic Crimping Tools are designed with user convenience in mind. Intuitive controls, such as one-touch operation and automatic pressure release mechanisms, simplify the crimping process and ensure consistent results. Many models come equipped with LED indicators to display battery status and operational readiness, providing users with real-time feedback for seamless workflow management.

Ergonomic handles and anti-slip grips further enhance comfort and safety, enabling precise handling even in challenging conditions. The compact design ensures easy storage and transportation, making it a practical addition to any professional toolkit.

Versatility Across Applications

These tools cater to a wide array of applications, making them indispensable in various industries. From installing electrical circuits and maintaining power lines to assembling high-performance industrial equipment, Battery Powered Hydraulic Crimping Tools offer unmatched versatility. They are compatible with interchangeable crimping dies, allowing professionals to adapt to different connector sizes and shapes without needing multiple tools.

For those working on sensitive electrical systems, the precision and reliability of these tools minimize the risk of system failures and enhance operational safety. This makes them a preferred choice for electricians, linemen, and industrial engineers alike.

Advanced Battery Technology

At the heart of these tools lies their advanced battery technology, which ensures consistent power delivery and prolonged usage. High-capacity lithium-ion batteries provide optimal energy efficiency, enabling users to handle demanding tasks without interruptions. Many models feature fast-charging capabilities, allowing the battery to reach full capacity in under an hour.

For added convenience, some tools include spare batteries and multi-voltage chargers, ensuring that professionals are always equipped with sufficient power. This feature is especially beneficial in remote or off-grid locations where access to charging facilities is limited.

Built for Durability

Battery Powered Hydraulic Crimping Tools are built to withstand the rigors of tough working environments. Constructed with high-strength materials, these tools are resistant to wear, corrosion, and impact, ensuring longevity and reliability. The robust hydraulic system is designed for high-performance applications, maintaining consistent pressure even under challenging conditions.

Plumbing industry.

| Output | 60KN |

| N.w./G.w. | 2.5kg/5.5kg |

| Stroke | 30MM |

| Dies range | DN15/DN20/DN25 |

| Output | 60KN |

| N.w./G.w. | 2.5kg/5.5kg |

| Stroke | 30MM |

| Dies range | TH16/TH20/TH25/TH32 |

| Output | 60KN |

| N.w./G.w. | 2.5kg/5.5kg |

| Stroke | 30MM |

| Dies range | U16/U20/U25/U32 |

Hydraulic Crimping Tools for U TH V DN Jaw.

Fast crimp and endurable.

| TECHNICAL | PARAMETERS |

|---|---|

| Crimping force | 60 KN |

| Crimping Range | 16-300mm² |

| Stroke | 17mm |

| Crimp/Charge | Approx. 320(Cu150mm²) |

| Crimping Cycle | 3-6S(Depending on the cable diameter) |

| Voltage | 18V |

| Capacity | 5.0Ah |

| Charging Time | 2 hours |

| Package | plastic box |

| Accessories | Crimping Die: 16,25,35,50,70,95,120,150,185,240,300mm²; Battery2pcs, Charger1pc |

Economical, practical and convenient crimping tool.

| Parameter | Value |

|---|---|

| Item No. | YKG-71500 |

| Crimping Range | 5/16"-5/8" |

| Max Force | 80KN |

| Max Stroke | 22mm |

| Dies | 65RB, 6-85RB, 105RB, 12, SRB, 8, 10, 12 |

| Application | Auto A/C hose crimping |

| N.W./G.W. | 3KG/6.5KG |

| Unit | mm |

| Note | There may be errors in manual measurement. |

1. Split-type mold (opening and closing type)

Structural features: The mold is divided into "upper mold" and "lower mold", connected by hinges or guide rails, which can be opened and closed. When pressing, the pipe material / pipe fittings are placed in the mold cavity, and then pressure is applied after closing.

Core application: ① "Fixed pipes" that have been laid (such as short pipes extending from the wall); ② Large-diameter pipe materials (DN63 and above), as the overall mold is heavy, the split type is easier to operate.

Advantages: ① No need to insert the pipe from one end into the mold, suitable for "mid-section connection"; ② The mold is easy to disassemble and assemble, facilitating the replacement of different specifications; ③ Low maintenance cost, individual mold pieces can be replaced separately when damaged.

2. Integrated mold (cylinder type)

Structural features: The mold is in the form of an "integral cylinder", and the pipe material needs to be inserted from one end of the mold, and then the other end is pushed out to connect with the pipe fitting, and then pressed.

Core application: ① "Straight pipe connections" that have not been laid (such as factory-premade pipes); ② Small-diameter pipe materials (DN16-DN50), with high press-fitting efficiency.

Advantages: ① The force is more evenly distributed during pressing, resulting in high connection accuracy; ② The mold has good sealing performance, preventing the pipe material from shifting during pressing; ③ Small in size and light in weight, suitable for handheld electric pipe pressers.

Copper bars are widely used in electrical, construction, and industrial applications. To meet the demands of modern manufacturi...

READ MOREWorking with electrical connections often requires precision, stability, and reliability. Tools like Battery Pipe Crimping Plie...

READ MOREPipe connection work often comes down to accuracy, control, and reliability. In many plumbing and maintenance tasks, Manual Pip...

READ MOREManual wire crimping pliers are essential tools for electricians, hobbyists, and DIY enthusiasts. They allow users to connect w...

READ MOREElectric wiring projects, whether at home, in offices, or on industrial sites, require reliable tools for secure connections. E...

READ MORECopper bars are widely used in electrical, construction, and industrial applications. Producing high-quality copper bars requir...

READ MOREProduct

Plumbing Tool Crimping Tool Cable Cutter Holemaking Pump Cutting,Bending,Punching Tool Cylinder Cable Stripper Pipe Bender Angle Iron Processing Machine Other Tools

Keep In Touch