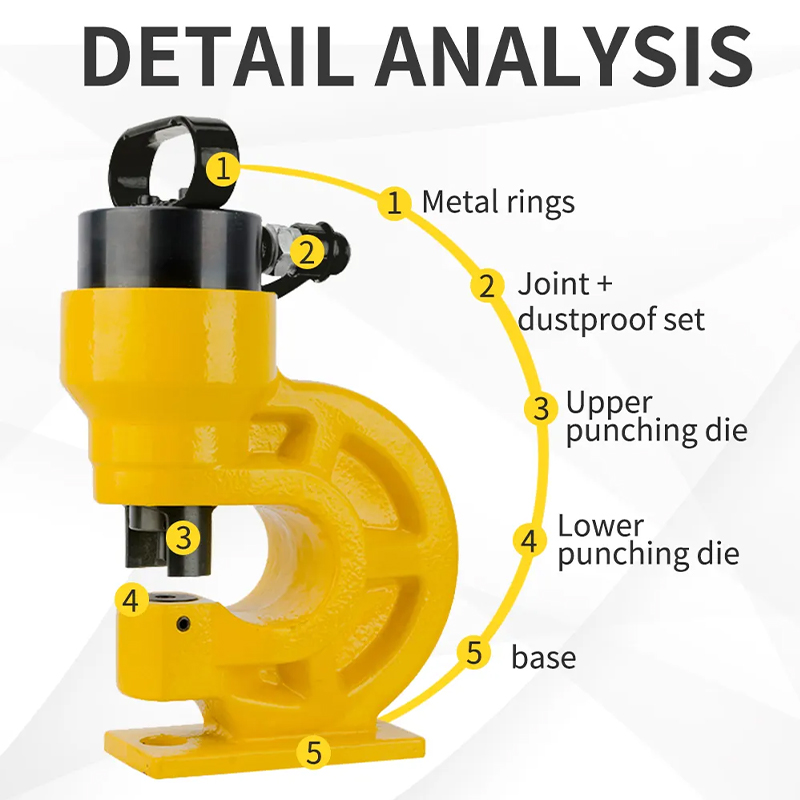

Introduction to the Punch Tool

The Punch Tool is a versatile and essential instrument in various industries, designed to create precise holes or indentations in materials. This tool is integral for tasks ranging from metalworking and woodworking to crafting and manufacturing. Its reliability and efficiency make the Punch Tool a valuable asset for professionals and hobbyists alike.

Key Features of the Punch Tool

Durable Construction

The Punch Tool is built with high-quality materials, ensuring durability and longevity. Its robust design can withstand heavy use and resist wear and tear, making it suitable for demanding applications.

Constructed from hardened steel or other resilient alloys, the Punch Tool maintains its sharpness and effectiveness over time.

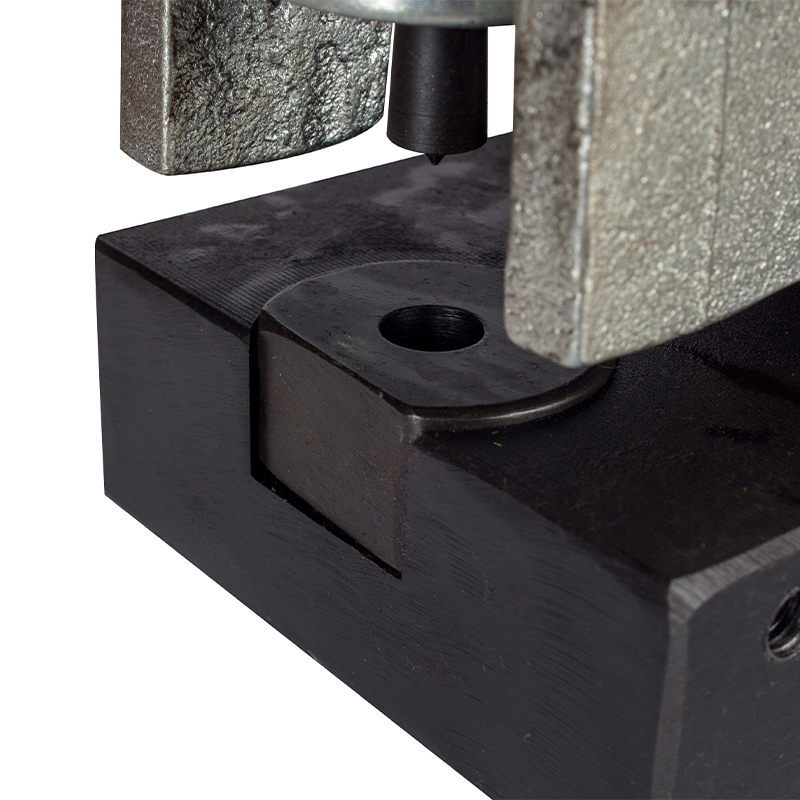

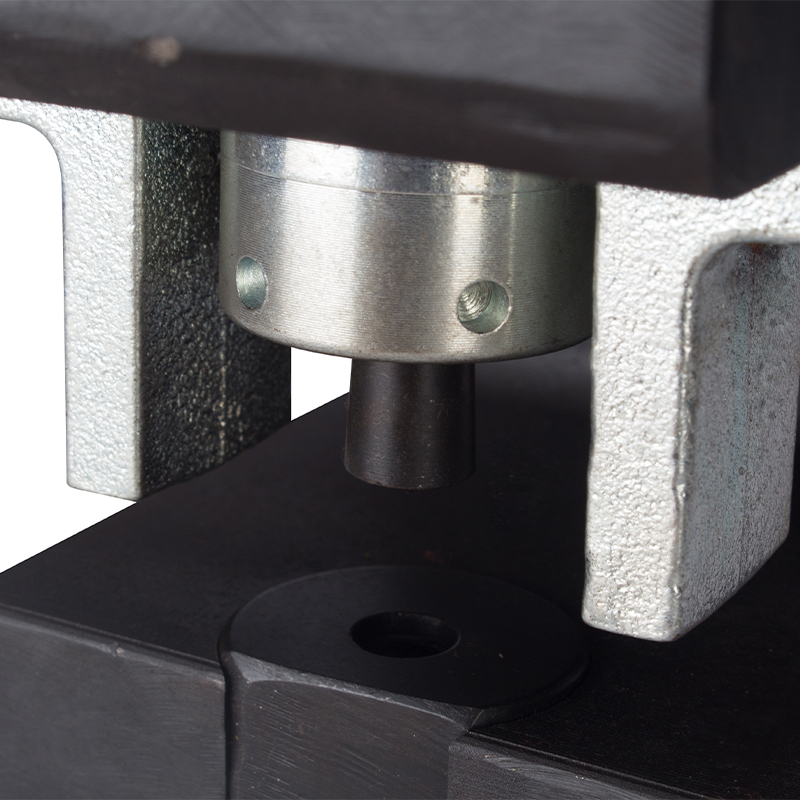

Precision and Accuracy

One of the standout features of the Punch Tool is its ability to deliver precise and accurate results. This tool is engineered to create uniform holes or indentations, which is crucial for projects requiring high levels of precision.

The Punch Tool often includes adjustable settings to accommodate various sizes and types of punches, enhancing its versatility and ensuring that it meets specific project requirements.

Ergonomic Design

The Punch Tool is designed with user comfort in mind. Ergonomic handles or grips reduce hand fatigue and provide better control, allowing users to operate the tool more effectively.

Its design also promotes ease of use, making the Punch Tool accessible for both experienced professionals and beginners.

Advantages of Using the Punch Tool

Efficiency in Operation

The Punch Tool streamlines the process of creating holes or indentations, significantly improving efficiency compared to manual methods. Its effectiveness speeds up production and reduces labor time.

With the Punch Tool, tasks that would otherwise be time-consuming and labor-intensive can be completed quickly and accurately.

Versatility Across Materials

The Punch Tool is adaptable to various materials, including metals, plastics, and wood. This versatility makes it a valuable tool for multiple applications, from crafting to industrial manufacturing.

By using the Punch Tool, users can handle a wide range of projects without needing multiple specialized tools.

Cost-Effectiveness

Investing in a high-quality Punch Tool can be cost-effective in the long run. Its durability and efficiency reduce the need for frequent replacements and repairs, offering better value for money.

The tool’s ability to perform multiple functions can also the need for additional equipment, further saving on costs.

Applications of the Punch Tool

Manufacturing and Fabrication

In manufacturing settings, the Punch Tool is used to create holes for fasteners, screws, or other components. Its precision ensures that parts fit together seamlessly, contributing to the overall quality of the finished product.

The Punch Tool is also employed in metal fabrication for tasks such as punching out shapes or creating perforations.

Woodworking and Crafting

For woodworking enthusiasts and crafters, the Punch Tool provides a reliable method for making decorative holes or indentations. Its versatility allows for creative applications in various projects.

The Punch Tool is also useful for making precise cuts in craft materials, enabling detailed and accurate work.

Automotive and Construction Industries

In the automotive industry, the Punch Tool is used for tasks such as creating mounting holes or aligning parts during assembly. Its precision and durability are essential for maintaining high standards in vehicle manufacturing.

Similarly, in construction, the Punch Tool facilitates the installation of fixtures and fittings by providing accurate hole placement.

Conclusion

In summary, the Punch Tool is a highly effective and versatile instrument that offers significant benefits across different applications. Its durable construction, precision, and ergonomic design make it an essential tool for professionals and hobbyists. By choosing the Punch Tool, users can enhance their efficiency, handle a range of materials, and achieve high-quality results in their projects.

YunGang Industrial Zone, Yuhuan County, Zhejiang province, China

YunGang Industrial Zone, Yuhuan County, Zhejiang province, China  +86-18967680938

+86-18967680938

Language

Language