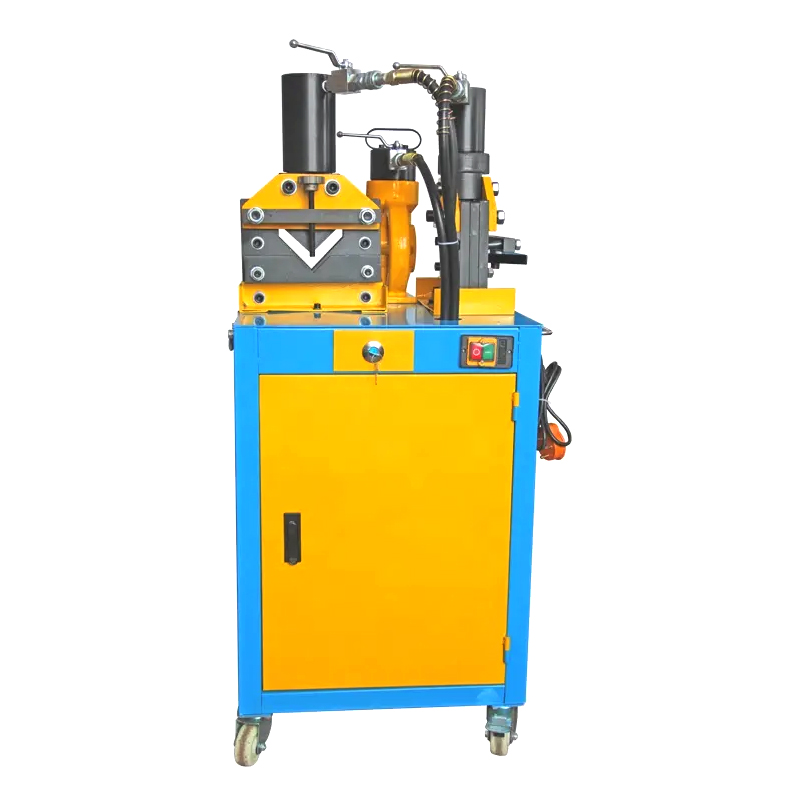

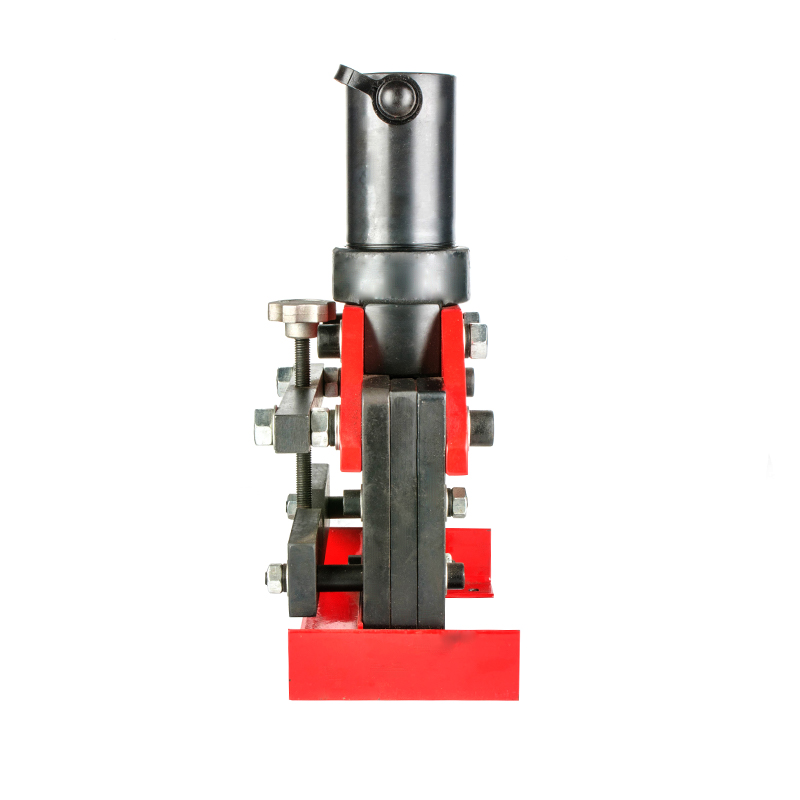

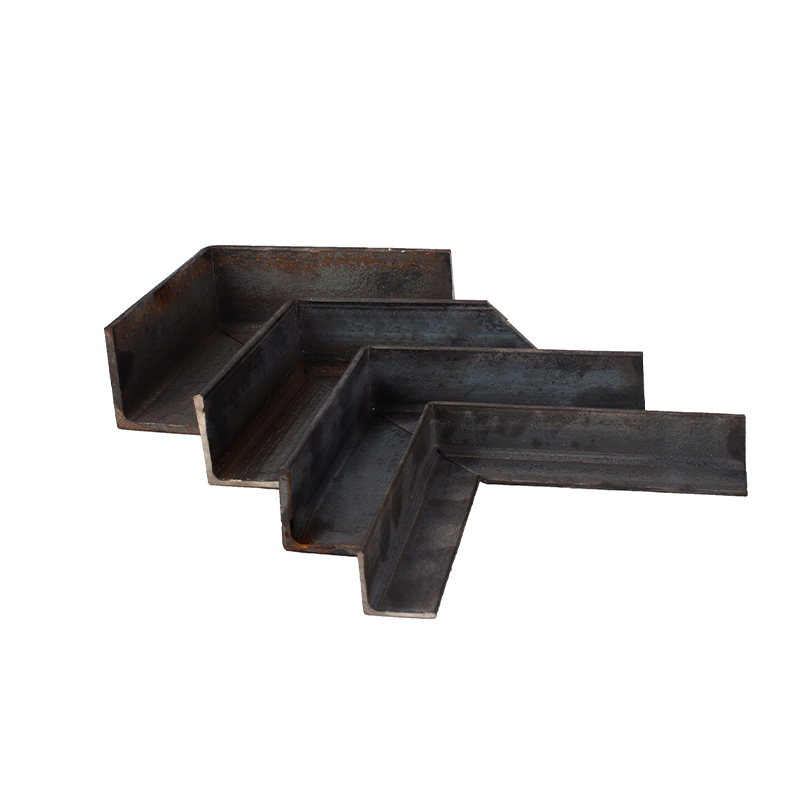

The Angle Iron Processing Machine is a versatile and efficient piece of equipment designed for the precise cutting, punching, and bending of angle irons. Angle irons are widely used in various industries, including construction, manufacturing, and metalworking, due to their strength and stability. This machine is engineered to streamline the processing of angle irons, improving productivity and ensuring high-quality output.

Key Features

The Angle Iron Processing Machine comes equipped with several essential features that make it a valuable addition to any workshop:

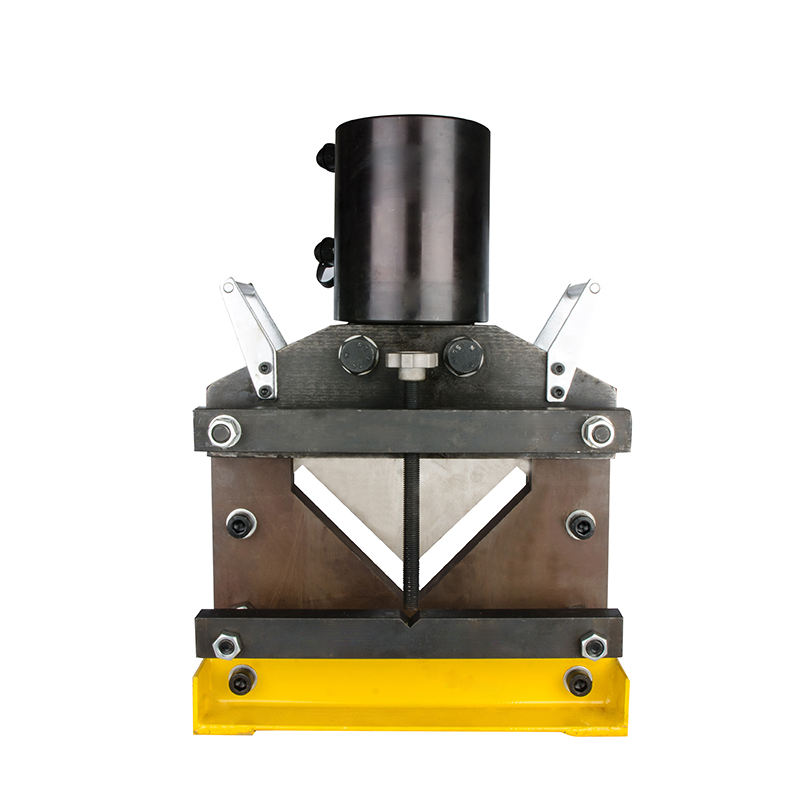

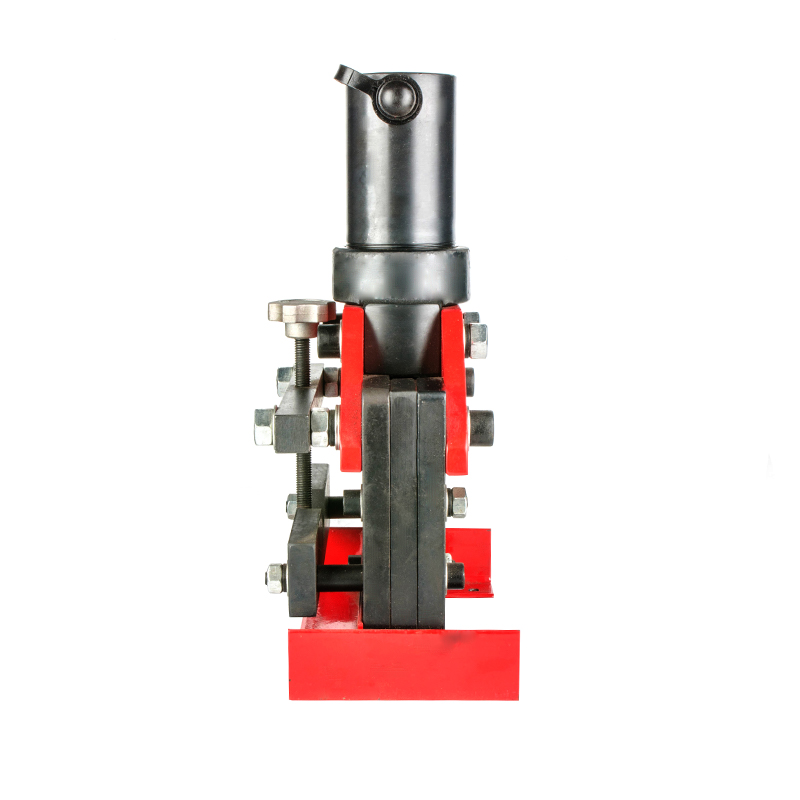

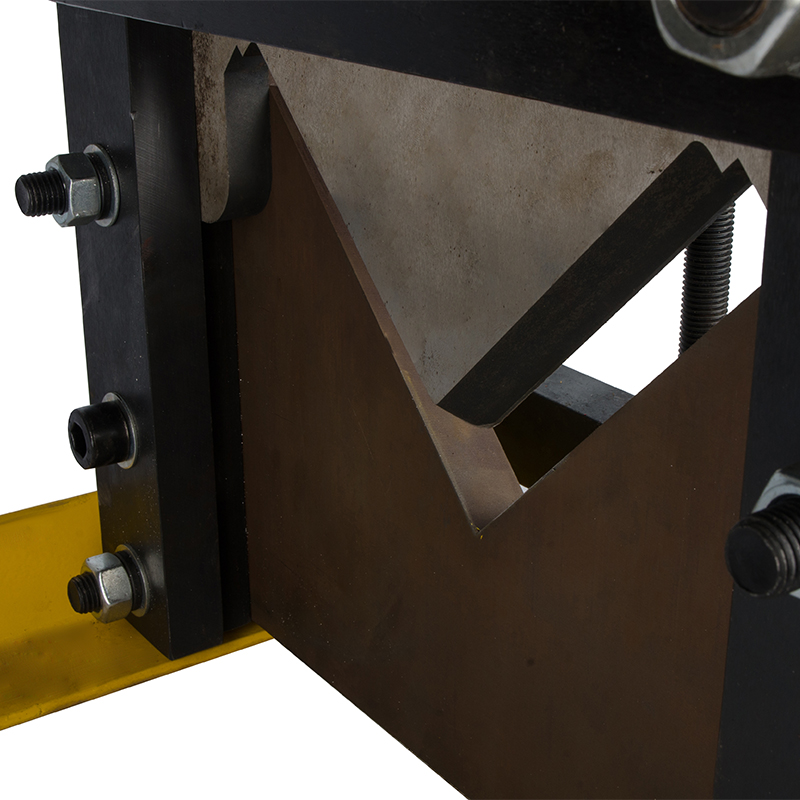

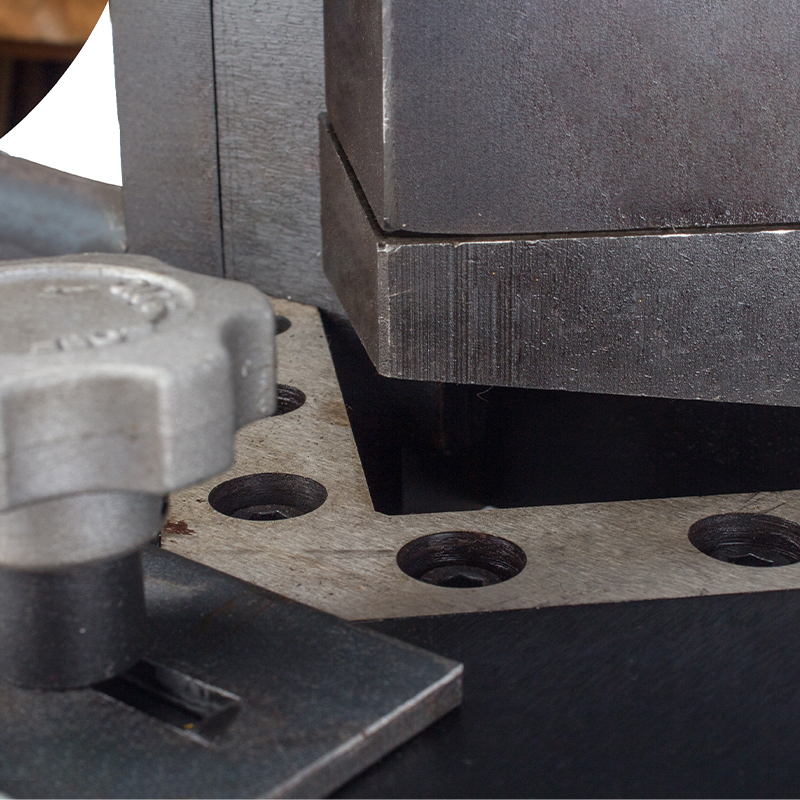

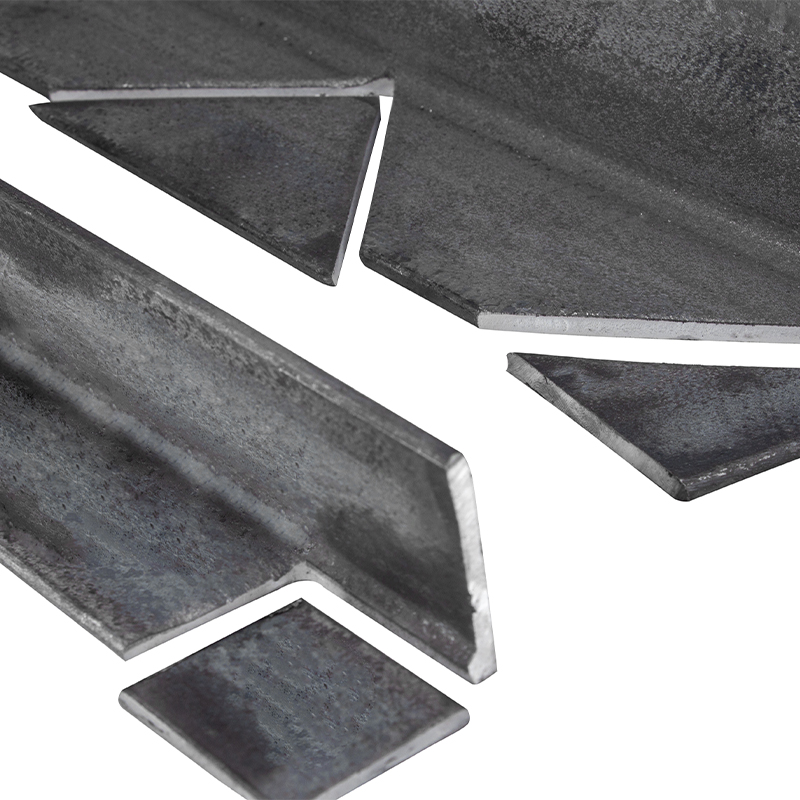

Precision Cutting: The machine is capable of cutting angle irons with high accuracy, ensuring that the dimensions are precise. This feature is critical in applications where exact measurements are necessary to maintain structural integrity.

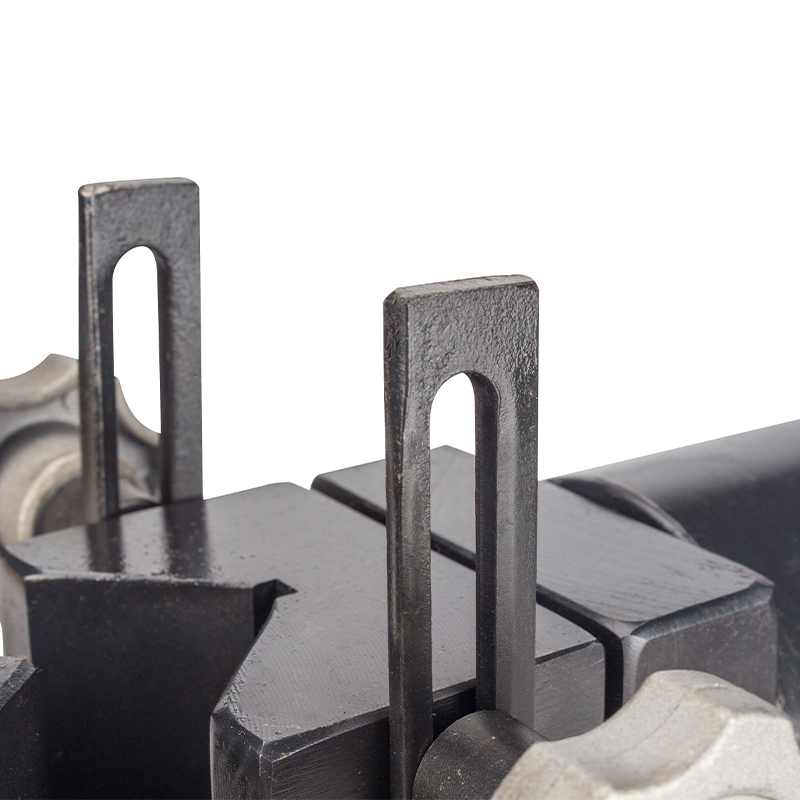

Punching Capability: The Angle Iron Processing Machine can also punch holes in angle irons, allowing for easy assembly and fastening. The punching process is smooth and efficient, reducing the risk of material deformation.

Bending Functionality: In addition to cutting and punching, the machine offers bending capabilities. This allows users to shape angle irons according to specific design requirements, providing greater flexibility in the manufacturing process.

Advantages

There are several advantages to using the Angle Iron Processing Machine in industrial settings:

Enhanced Efficiency:

Streamlined Operations: By combining cutting, punching, and bending in one machine, the Angle Iron Processing Machine reduces the need for multiple pieces of equipment, to more streamlined operations.

Time-Saving: The integration of these functions saves time by eliminating the need to transfer materials between different machines, thus speeding up the production process.

Cost-Effective:

Reduced Labor Costs: The machine’s automation capabilities reduce the need for manual labor, which can significantly lower operating costs.

Minimized Material Waste: Precision cutting and punching material waste, can result in cost savings over time.

Versatile Applications:

Multi-Industry Use: The Angle Iron Processing Machine is suitable for a wide range of industries, from construction to automotive manufacturing, making it a versatile tool in any production environment.

Customizable Outputs: The machine can be adjusted to produce customized outputs, meeting the specific needs of different projects.

Reasons to Choose the Angle Iron Processing Machine

Choosing the Angle Iron Processing Machine offers several benefits for businesses looking to enhance their production capabilities:

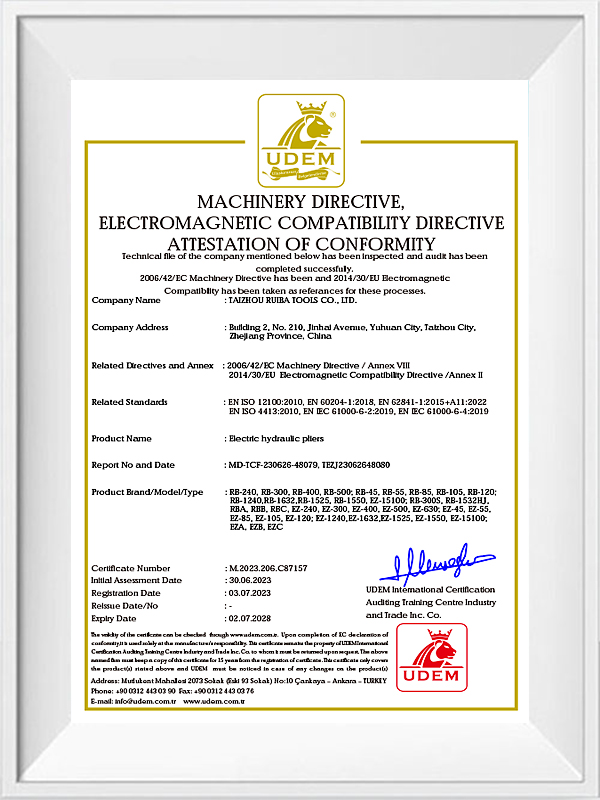

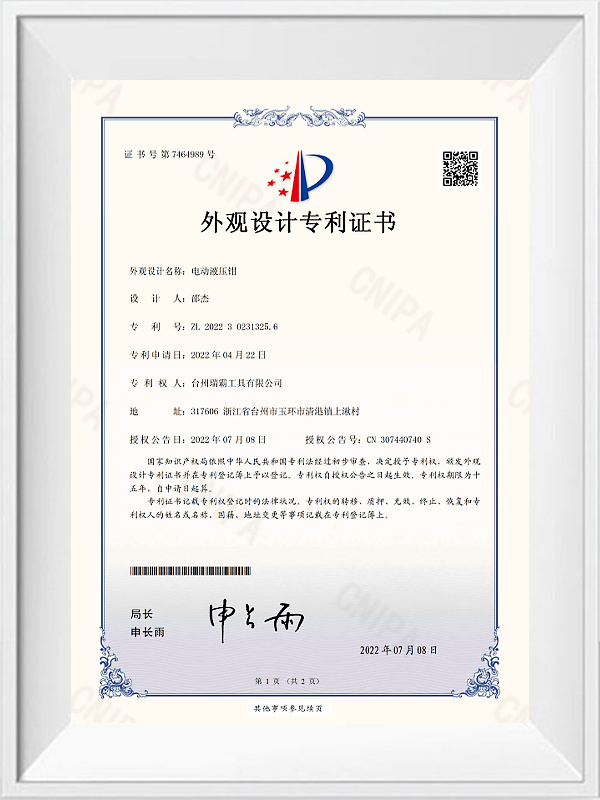

Durability and Reliability: Constructed with high-quality materials, the Angle Iron Processing Machine is built to withstand the demands of heavy-duty industrial use. Its robust design ensures long-term reliability, downtime, and maintenance costs.

User-Friendly Interface: The machine features an intuitive interface that simplifies operation, even for those who are not highly experienced in metalworking. This user-friendly design helps reduce the learning curve and ensures that the machine can be operated efficiently with training.

Safety Features: The Angle Iron Processing Machine is equipped with several safety features that protect operators from accidents. These include emergency stop buttons, protective shields, and automatic shut-off mechanisms that activate in case of malfunction.

Summary

In conclusion, the Angle Iron Processing Machine is an invaluable asset for any industry that requires precise and efficient processing of angle irons. With its combination of cutting, punching, and bending capabilities, this machine streamlines production, reduces costs and enhances productivity. Its durable construction, user-friendly interface, and comprehensive safety features make it a reliable choice for businesses seeking to improve their manufacturing processes. Whether you are in construction, automotive, or general metalworking, the Angle Iron Processing Machine is a versatile tool that can meet your specific needs.

YunGang Industrial Zone, Yuhuan County, Zhejiang province, China

YunGang Industrial Zone, Yuhuan County, Zhejiang province, China  +86-18967680938

+86-18967680938

Language

Language